Experience is our way of setting the bar higher

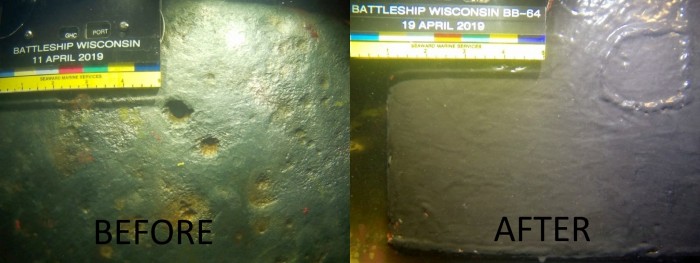

Seaward Marine Services was tasked with the restoration of the Sea Chest Box Attachments("Box Blanks") on the Battleship Wisconsin. The Wisconsin's box blanks were cleaned, inspected, and 62 were repaired using Hycote 151 underwater epoxy coating application. Work was performed April 8-22 by Seaward's dive boat Coastal Pride and crew, Dive Supervisor Bill Greenwood, and Project Manager Mike Charles.

Posted on: 30/Apr/2019

Cecil C. Achord

Keystone Shipping Company contracted Seaward Marine Services to provide diving services in support of two separate MARAD USNS Turbo-Activations is Charleston, SC. Turbo- Activations are no-notice readiness exercises for the prepositioned ships to get the vessels tested and underway within 96 hours.

Posted on: 26/Mar/2019

Cecil C. Achord

Crowley Government Services has awarded Seaward Marine Services Norfolk a USNS Multi-Ship contract to provide diving services on USNS Obregon, USNS Pless, and USNS Kocak in Newport News VA. Work to be completed by Seaward Marine Services Dive Vessel Coastal Pride crew includes cleaning and inspecting the propellers, rudders, depth sounder fathometers, and Doppler speed logs.

Posted on: 05/Mar/2019

Cecil C. Achord

Seaward was featured on Manufacturing Marvels, a 2 minute promotional video, which aired on the Fox Business Channel, February 11, 2019.

Posted on: 12/Feb/2019

Cecil C. Achord

Mid Atlantic Engineering and Technical Services has awarded Seaward Marine Services, LLC a firm fixed Purchase Order to provide Diving Services on the USNS Megar Evers (T-AKE-13).

The scope of work included main propeller and hub propeller cleaning and polishing, weardown readings, and inspection of the Underwater Hull, Propeller, Bow Thruster, Bilge Keels, Sea Chests, and Tail Shaft. Diving Operations were carried out Feb 4-8 by Seaward's Mobile Two.

Posted on: 08/Feb/2019

Cecil C. Achord

Walashek Industrial awarded Seaward Marine Services, LLC Norfolk, a firm fixed Purchase Order to accomplish a Full Clean and DataScan Hull Survey, of the Navy Barge IX-516 at the Nuclear Propulsion Training Unit Goose Creek Charleston, SC. Period of performance was January 14-21, 2019. Work was accomplished by Seaward MOB-1 out of Mayport, FL, and the Datascan/Lampray team out of Norfolk.

Posted on: 24/Jan/2019

Cecil C. Achord

Anglo-Eastern Ship Management Ltd has awarded Seaward Marine Services, LLC firm a fixed Purchase Order an ABS underwater hull inspection in lieu of dry-docking (UWILD) for the bulk carrier AM Ghent.

Work was performed October 3rd at DTA Terminal Newport News, VA by Seaward Marine Dive Vessel Coastal Pride and Crew.

Posted on: 04/Oct/2018

Cecil C. Achord

Seaward Marine Services would like to thank the Historic Naval Ships Association for having us at their annual conference which was held this year in Bremerton, WA and the Kitsap Conference Center for hosting the event. We'd like to thank all those who came by our booth this year, and hope that more museum ships will begin to utilize and count on our services the way our current museum ship customers have. Thanks again, and always looking forward to doing what we can to help you preserve naval history.

Posted on: 01/Oct/2018

Cecil C. Achord

Keystone Shipping Services has awarded Seaward Marine Services, LLC firm a fixed Purchase Order to provide cleaning and inspection of the MV Cape Rise(T-AKR-9678) in support of a turbo activation.

The scope of work included cleaning and inspection of underwater hull, rope guard, rudder, bilge keels, gratings, propeller, rudder, bow and stern thrusters. Work was performed September 27-28 by Seaward Marine Services Dive Vessel Coastal Pride and Crew.

Posted on: 29/Sep/2018

Cecil C. Achord

US Marine Management, Inc.(USMMI) has awarded Seaward Marine Services, LLC firm a fixed Purchase Order to provide cleaning and inspection of the USNS Brittin (T-AKR 305) and USNS Mendonca (T-AKR 303), with the USNS Brittin cleaning being in support of a turbo activation.

The scope of work included cleaning of propellers, rudders, sea chest gratings, bow thruster units, and inspection of the underwater hulls and appendages. Work was performed September 20-26 by Seaward Marine Dive Vessel Coastal Pride and Crew.

Posted on: 27/Sep/2018

Cecil C. Achord